Heavy Trucks: Specialised Fasteners

Supply chains have always been prone to disruption, influenced by anything from shipping delays to customs clearance issues. 2022, however, has seen exceptional disorder, brought on by the aftereffects of the COVID-19 pandemic and political instability in Eastern Europe.

Heavy truck manufacturers especially are under pressure to rapidly produce vehicles. Not only do supply chains heavily rely on these vehicles to get products from A to B, but manufacturers are struggling to source the materials to manufacture these vehicles in the first place.

Alongside this and pressure from governments and consumers to shift to eco-friendly technologies like electric and hydrogen, heavy truck manufacturers are under pressure to produce especially durable vehicles that offer significant power and torque output to carry heavy loads. It’s crucial, therefore, that manufacturers use quality parts to avoid excessive maintenance and vehicle downtime.

The heavy truck market was valued at around $205 billion in 2021, and is expected to reach $314 billion by 2027. To meet this intense demand, then, it’s also important for manufacturers to streamline their supply chains so they receive these quality parts at the right place, at the right time.

Quality Parts on a Large Scale

Trucks need to offer significant torque output over especially long distances while often withstanding extreme temperatures. Quality parts have a significant impact on vehicle performance, including fasteners. Fasteners may make up only 1% of a project’s budget, but they make up nearly 50% of a product’s parts. Using durable fasteners at every opportunity, therefore, is crucial.

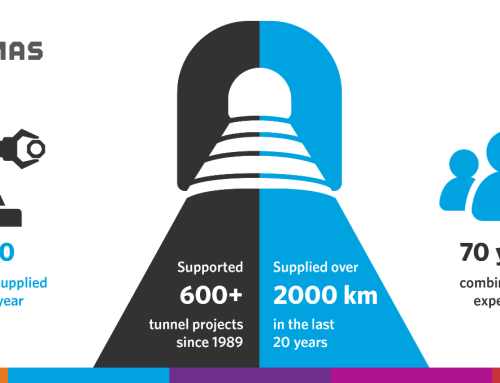

At Optimas, we manufacture quality fasteners through state-of-the-art cold-forming processes.

Cold-forming maximises a part’s metallurgical properties, prioritising strength and durability by ensuring the part’s structural integrity, meaning they’re ideal for heavy trucks. We’re also experts in working with exotic materials, like titanium, copper, stainless steel and aluminium. This means we can manufacture parts that are lightweight, durable and corrosion resistant, depending on your need.

Depending on the geometry and material used, an experienced cold-form manufacturer can work as accurately as within a thousandth of an inch, and Optimas has the machinery to produce fasteners of very specific diameters and dimensions. Our cold-forming machines can handle parts from 2mm to 18mm in diameter and in lengths from 6 to 175mm, while our advanced bar turning capabilities can produce low quantity, high quality parts ideal for prototyping at the design stage.

Cold-forming produces specialised and durable parts and does so on a very large scale with virtually 0% waste. Cold-form manufacturing can produce hundreds of millions of parts a year, allowing manufacturers to efficiently handle full-scale production and meet high-demand periods.

Streamlining your Supply Chain

Not only do we manufacture quality parts, but we source and distribute them too. Our supply chain solutions can help heavy truck manufacturers streamline production processes by reducing risk, improving lead times, and boosting productivity.

We competitively source our fasteners, C-Class components and MRO parts from over 4000 global suppliers, meaning that whatever the state of supply chains, you can rely on a well-stocked inventory. If you’re based in the UK or the US, by sourcing your parts from Optimas you’ll also benefit from onshoring, as we’re the only manufacturer with cold-form facilities on both sides of the Atlantic.

Here are just a few examples of heavy truck fasteners that we produce and supply:

- Truss head lockbolts

- Full collar lockbolts

- Breakstem rivets

- Socket cap screws

- Flat, lock and split washers

With 100 years’ experience manufacturing fasteners of varying dimensions and material types, Optimas can produce and supply specialised parts for any heavy truck application. Work with us to maximise your product quality and meet demand.