SERVICES

Even the smallest parts can make a big impact on your business. That’s why we’re focused on finding solutions that improve efficiency and drive profitable growth across your enterprise.

We Understand Your Challenges

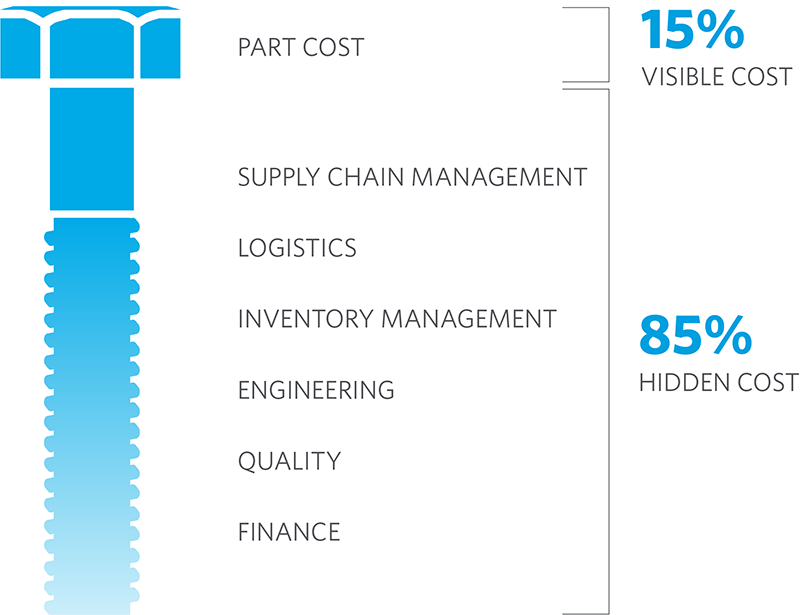

From reducing total cost of ownership to having the right quality product in stock to understanding part consumption, you need a partner who can create value across your entire enterprise.

We focus on all the hidden costs of parts management.

MINIMIZE YOUR

SUPPLY CHAIN RISK

Stay competitive with a streamlined supply chain, global sourcing and readily available inventory.

OPTIMIZE YOUR

INVENTORY

Produce more with less. Reduce your inventory, eliminate waste and prevent downtime.

ENHANCE YOUR

OPERATIONS

Do more with less. Free up your staff to focus on what matters most.

IMPROVE YOUR

QUALITY

Manufacture cutting-edge products that your customers trust with a “best-in-class” product range.

The simplified component selection and supply chain that Optimas recommended and manages is helping to significantly reduce costs, minimize risk in the supply chain and increase efficiency. This allows us to focus on growth of our high-performance trains in the UK.

– Robert O’Hara, Category Lead, Interior & Car Body