Durable & Lightweight Fasteners for Automotive Exhaust Systems

Durable and lightweight fasteners are essential for the production of automotive exhaust systems. Despite the rise of alternate fuels such as electricity and hydrogen, traditional internal engine combustion vehicles are still in high demand. The automotive exhaust market is expected to register a CAGR (compound annual growth rate) of 7.42% between 2022 and 2027, so with the market predicted to flourish it is important to ensure manufacturers are maximising every component used in the build of their exhaust systems, including fasteners.

Operating under High Temperatures

Due to emission standards becoming increasingly more stringent, requiring engines to run at higher temperatures to improve overall vehicle efficiency, fasteners for automotive exhaust systems need to be able to keep exhaust components securely bolted together under high temperatures.

The increase in operating temperatures has resulted in an emerging need for fasteners which can maintain continued operational performance when subjected to high temperature ranges. For exhaust systems, any emissions leakage caused by joint relaxation or component failure can put the vehicle’s emissions systems in jeopardy, thereby negatively affecting its performance.

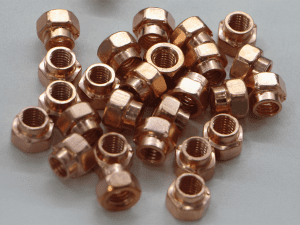

Copper locking bolts

One way to offset the rigours of operating in a high temperature environment when producing exhaust systems will often be to make use of studs and locking nuts finished with copper plate. Copper is better able to deal with the thermal expansion and contraction during the heating cycle of an exhaust system and can help ensure a seal is maintained on components between an operating temperature range of -94°F to 750°F, making these fasteners suitable for extreme heat conditions for automotive applications.

Lightweighting

Additionally, lightweighting of fasteners is another area of primary concern for automotive exhaust systems. Across all aspects of an automotive vehicle, there is a goal to reduce weight and fuel consumption to achieve lower CO2 emissions. Manufacturers are increasingly using tubular steel exhaust manifolds to help improve their overall efficiency. The type of material used to produce the exhaust manifold is extremely important because it determines the reliability and durability of the exhaust system.

Exhaust manifold

Using high strength steel, aluminium, carbon fibre or alloys to aid in lightweighting of fasteners can provide manufacturers with the weight reductions they need for their builds. A 10% reduction in vehicle weight can result in a 6-8% improvement in fuel economy, therefore optimising vehicle performance. The weight of fasteners used can also impact safety, as heavier components have the potential to increase any damage caused in a collision.

As with all areas within an automotive build, there exists the potential for failures to occur with prolonged usage. Within exhaust systems, poor road conditions can cause cracks to form in joints, resulting in the escape of toxic fumes with the potential for dispersal inside the cabin of the vehicle presenting a possible risk to the health of occupants inside. This issue can be mitigated through the use of quality high strength fasteners to ensure components in the exhaust system are as secure as possible.

Catalytic Converter Developments

One reason for the rise of the automotive exhaust system market is due to the development and refinement of catalytic converter systems. By the end of 2023, scientists at the University of Leeds are aiming to trial a new type of catalytic converter which accelerates the removal of harmful nitrogen oxides and carbon monoxide from engine fumes. The production of these new converters will utilise rarer specific materials to ensure it meets its efficiency goals, thereby increasing the costs associated with the production of exhaust systems.

As a result of these increased costs, it is key to maximise your efficiency and profitability when it comes to the fasteners used in your automotive builds. Here at Optimas we can help you stay competitive with a streamlined supply chain, global sourcing, and readily available inventory to minimise your overall supply chain risk.

Get in touch with our experts to optimise your products.