Optimised Fasteners for Automotive Wheels

The automotive industry continues to grow, and in particular so does the automotive wheel market. The global automotive wheel market size was valued at $31.4 billion in 2021 and is expected to register a compound annual growth rate (CAGR) of 6.10% from 2023-2028, so it’s clear the market is continuing to drive onwards.

Fastener Demand

Torque limited wheel gun

Automotive wheel systems predominately use wheel bolts or wheel studs and nuts, and these fasteners are subject to high-quality design, manufacture and assembly. These fasteners need to meet the highest demands on performance and longevity.

Additionally, security is an important aspect for consideration in automotive wheel fasteners. The anti-theft designs of these fasteners help ensure that it is more difficult for criminals to remove wheels or tyres from vehicles due to the required use of uniquely designed locking keys when removing locking wheel nuts.

Fasteners utilised in automotive wheel applications are required to meet high tolerance demands, bearing loads between 65-90% of their yield strength so they don’t loosen in their application, or worse, shear. Additionally fasteners used in wheel applications also need to be able to resist significant vibration to maintain clamp load effectively. Failure to use incorrect or insufficient quality wheel bolts or nuts may potentially cause the wheel to loosen, tire pressure to be lost and adversely affect handling, leading to a loss of vehicle control which could result to personal injury.

Calibrated torque wrench

Automotive wheel fasteners also need to be highly corrosion resistant to withstand environmental conditions, like extreme heat and cold, salt from gritted roads, as well as chemicals used in processes like car washing. Using fasteners that are produced from corrosion resistant materials or are finished in a corrosion resistant plating, can increase a vehicle’s durability by ensuring its key components are optimised for different environments and temperatures.

In addition to those factors, ensuring the wheel is as lightweight as possible is key for any automotive build. A surplus weight increase by fasteners can lead to a decrease in less fuel efficiency, increase in harmful emissions, and may add pressure on the vehicles tyres reducing their lifespan and resulting in additional safety concerns.

When Fasteners Fail

Through improper installation methods, unsuitable manufacturing processes or improper testing of fasteners, there are a range of factors that can result in fastener failure and lead to huge safety implications.

Damaged wheel bolts

A recent study on the automotive industry in the United States found that 23% of service problems were attributed to relaxation of threaded fasteners and 12% of new vehicles have experienced substandard clamp load of their thread fasteners.

Consequently, it is extremely important to ensure automotive wheel fasteners are tightened to the specified torque for the fastener and application. This torque value will be determined by a range of factors including diameter, tensile strength, bearing surface area and coefficient of friction. Wheel bolts or nuts on vehicles should always be tightened using calibrated specialised tools such as torque limited air wrenches and always checked by using a torque wrench, and never by judgement alone. Mounting wheel bolts should only begin by hand to avoid misalignment of the fastener and damage to its seat, and the correct tools need to be used to control the tightening torque.

Broken wheel nuts

In the case of some failures, incorrect fastener selection can be the cause for the vehicle’s failure. If the bolts are too long, they can create a clash condition potentially interfere with other parts, which is fraught with wheel locking. It’s also vital to use the correct type of fastener with the required mount. For example, use of conical seat fasteners in the wheels with spherical mounting seats and vice versa leads to misalignment of the wheel to its rotation axis, causing the threaded connection to loosen.

The choice of corrosion protection on automotive fasteners such as wheel bolts is a key element in fastener selection. Due to the harsh operating environments in which a wheel bolt must operate, they may become susceptible to corrosion through oxidisation over time. To protect wheel bolts from corrosion-related failure, it is advisable to treat them during production by galvanising, anodising or electroplating.

Due to the load bearing nature of a wheel bolt, a common choice is to specify a high tensile fastener. High tensile fasteners where the core or surface hardness is above 320HV can become susceptible to Hydrogen Embrittlement. Hydrogen embrittlement occurs when fasteners become weakened and brittle as a result of the introduction and diffusion of hydrogen into the material during the electroplating process of finishing.

Mitigating the risk of Hydrogen Embrittlement can be done by ensuring the fastener is de-embrittled by correctly baking it within 4 hours of plating at a temperature of between 200ºC to 230ºC for between 2 hours – 24 hours.

Alternatively selecting a corrosion protection option which does not use an electroplating process and thereby eliminates the production of hydrogen gas caused by electrolysis, reduces the need for de-embrittling. Zinc aluminium flake finishes, applied through a dip spin method do not induce hydrogen embrittlement and are a safer option for use on high tensile fasteners like wheel bolts.

The Benefits of Cold forming Wheel Bolts

Damaged wheel bolt hole

One highly effective process for manufacturing wheel bolts is through cold-forming. Cold forming begins with a wire or rod which can be formed from a variety of materials, and through the use of punches and dies progressively forms the desired shape without material removal. This is a highly repeatable, cost-effective manufacturing option requiring minimal machining and little to no finishing work producing and has the benefit of producing minimal waste from the manufacturing process.

The cold forming process offers excellent dimensional accuracy at high-speed production rates, ensuring that the wheel bolt is consistent in size and shape, whilst meeting the demands of the automotive industry. This precision is vital for proper wheel assembly and safety.

In summary, cold forming is an advantageous manufacturing method for wheel bolts because it combines efficiency, precision, and material optimization, resulting in cost-effective, high-quality components that meet the stringent safety requirements of the automotive industry.

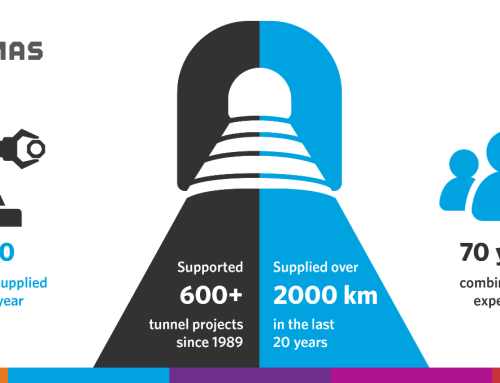

Optimas: Providing you with Engineering and Quality Solutions

For automotive manufacturers, Optimas can provide expert engineering services to ensure their automotive builds don’t encounter these potential issues and provide them with the quality fasteners they need for their vehicles.

To achieve a “best-in-class” product range of fasteners and components, our work goes beyond identifying the best suppliers. We conduct a rigorous qualification process to ensure suppliers can manufacture high-quality parts at the volumes you need, when you need them. We work with our suppliers to continuously improve their product performance and capabilities to support you in every aspect of your supply chain.

Plus, our dedicated team of fastener engineers across the world can work on a project basis or on-site with your engineering department. This close relationship allows us to play an active role from product development to assembly line where quality and productivity matter most. We focus on saving you money while maintaining or improving quality.

Optimas are also the only manufacturer with cold-form facilities on both sides of the Atlantic. By sourcing your nuts, bolts and screws locally and onshoring your supply, lead times can be significantly reduced from PO to delivery, and simplified transportation provides you with a more sustainable and efficient supply chain.

For efficiency, quality and security, partner with Optimas for your fasteners and let us de-risk your supply chain.