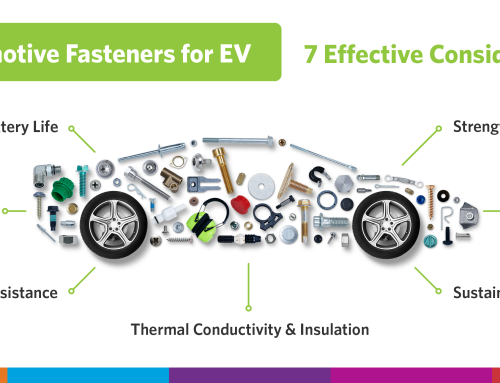

Standard, Specialised, Bespoke: Fasteners and Components for Automotive Interiors

From navigation systems to body panels, each aspect of an automotive interior requires durable, high-quality fasteners.

Making up around 50% of a vehicle’s Bill of Materials, fasteners and components for automotive interiors have a number of key conditions to satisfy, from passenger safety and comfort to technology user experience and vehicle performance. Plus, owing to the rising popularity of advanced infotainment systems, luxury vehicles, EVs, hybrids and in some cases, autonomous cars, manufacturers are turning to increasingly advanced fastening solutions.

Although standard fasteners still have their part to play in automotive interior builds, these parts need to be optimised for use. Depending on their application, fasteners and components for automotive interiors need to prioritise:

Lightweighting

- Lightweighting is important in any automotive build, but especially for vehicles powered by alternative fuels. A 10% reduction in vehicle weight can result in a 6-8% improvement in fuel economy, therefore optimising vehicle performance. The weight of fasteners used can also impact safety, as a heavier car will do much more damage in a collision.

Durability and Vibration Resistance

- Required to meet high tolerance demands, fasteners have to be able to bear loads between 65-90% of their yield strength so they don’t loosen in their application, or worse, break. Fasteners for automotive interiors also need to be able to withstand significant vibration to effectively hold the car together.

Thermal Conductivity and Insulation

- Prioritising thermal conductivity and insulation is key in manufacturing car batteries, particularly in the case of EVs and hybrids, to avoid depleting battery performance, over-heating and damage done by external conditions.

Electrical Connectivity

- To guarantee high performance in driver assistance, user experience, navigation and infotainment, automotive electrical systems require advanced fastening solutions that prioritise electrical connectivity.

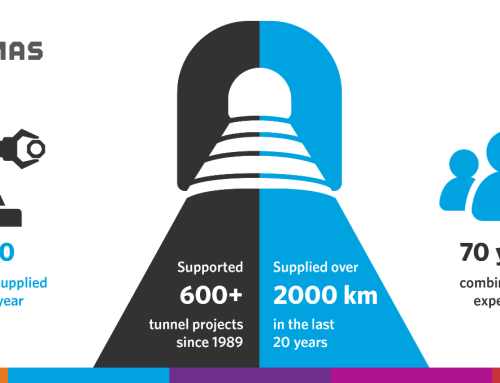

At Optimas, alongside manufacturing and distributing a range of standard and specialised fasteners and components, it’s our engineering capabilities that set us apart.

With decades of experience working with automotive OEMs, Optimas’ engineers specialise in providing expert technical support to our customers, focusing on product development, analysis and testing to lower cost and assembly time, increase manufacturers’ speed to market and improve product performance. As a Global PPAP Centre of Excellence, we also specialise in rapid PPAP approvals, ensuring our parts meet the most rigorous of quality standards.

Get in touch with us today to maximise your product quality.